Natural Rubber Wastewater Treatment

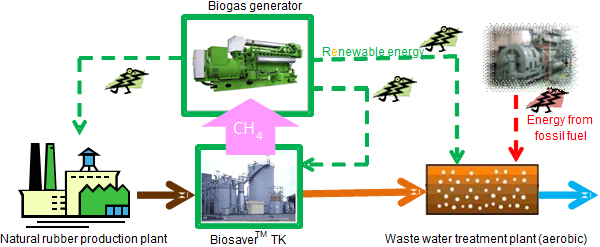

Treatment of natural rubber processing wastewater using a combination system of a two stage up flow anaerobic sludge blanket and down flow hanging sponge system.

Natural rubber wastewater treatment. The key factors evaluated in here comprised the following. Natural wastewater treatment systems are simple cost effective and efficient methods to purify the growing amount of wastewater produced by our society. The results revealed that the removal of ammonia nitrogen up to 79 5 from natural rubber wastewater. In this commentary the process performance of natural rubber processing wastewater systems was evaluated and compared.

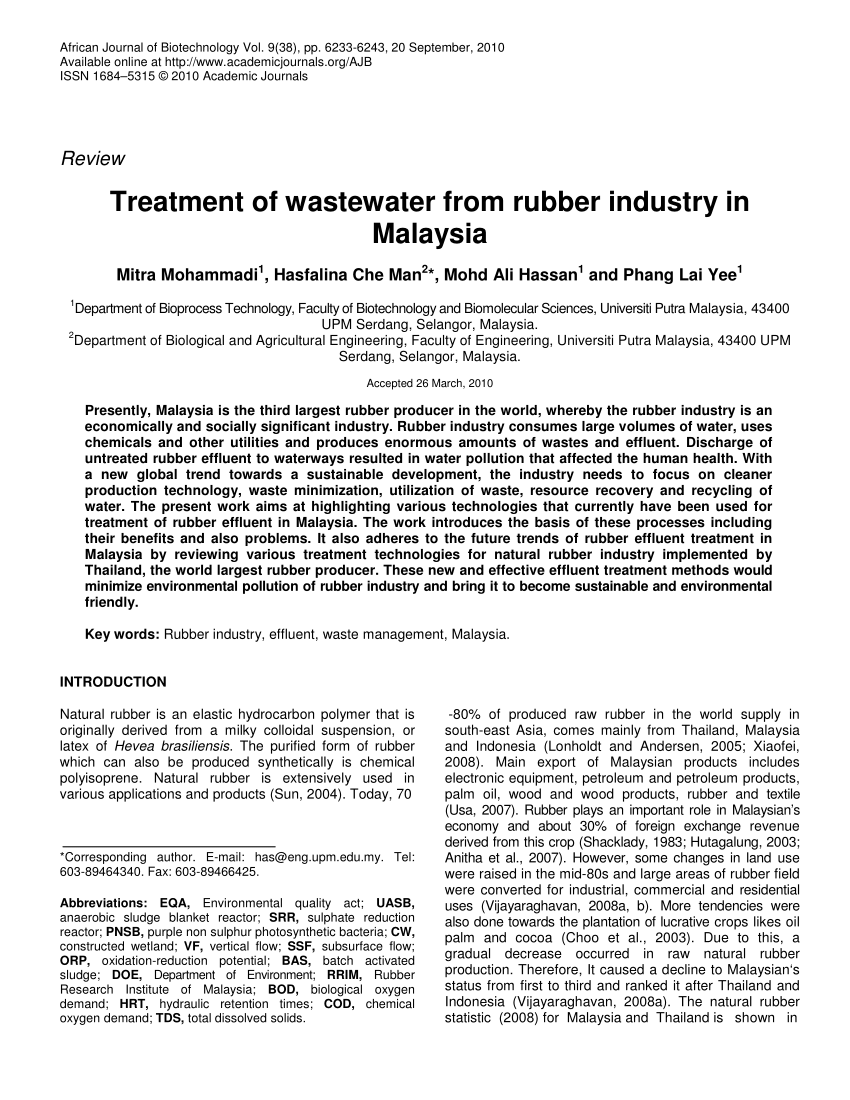

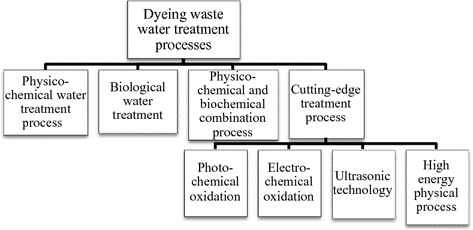

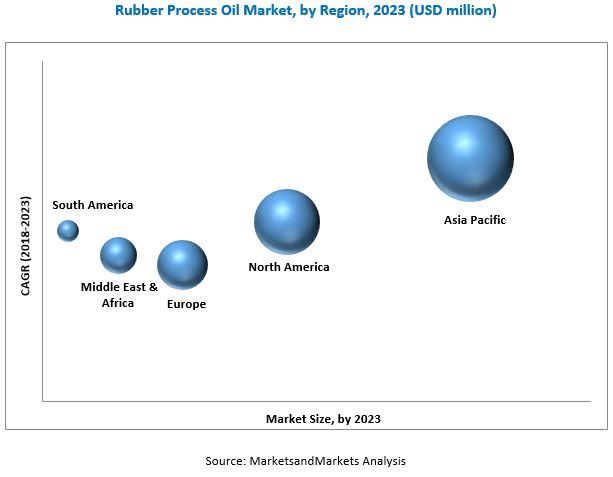

4 autumn 2015 rubber wastewater treated through physicochemical process is discharged into the ozonation reactor 50 liters for treatment by ozone figure 1. The type of wastewater the prevention of system clogging by coagulated rubber and the reduction of greenhouse gas ghg emissions. Tanikawa d 1 syutsubo k 2 hatamoto m 3 fukuda m 4 takahashi m 5 choeisai pk 6 yamaguchi t 3. Natural rubber processing sector consumes large volumes of water and energy and uses large amount of chemicals as well as other utilities.

Whatever processing procedures are used for preparing products. The adsorption efficiency of efb fibre was maximum at 3 5 g dosage ph 7 150 rpm shaking. In the treatment of natural rubber processing wastewater hydrogen sulfide inhibition and the clogging of the system by coagulated rubber need to be considered in the wastewater processing method used for cl and block rubber respectively. A pilot scale experiment of natural rubber processing wastewater treatment was conducted using a combination system consisting of a two stage up flow anaerobic sludge blanket uasb and a down flow hanging sponge dhs reactor for more than 10 months.

Schematic and photo of an ozonation pilot scale. In addition both ghg emissions and power consumption need to be reduced in wastewater treatment. Treatment of natural rubber industry wastewater massoudinejad et al. Wastewater is an unavoidable by product of rubber processing.

244 j adv environ health res vol. It also discharges massive amounts of wastes and effluents leong et al 2003. They can be applied as secondary or tertiary purification treatment allowing the removal of most of the bacteria microorganism and the destruction of the organic matter. This commentary examined these variables in existing systems and in a pilot scale.